Why should you use a single tag printer to print clothing hang tags?

A T-shirt with a hang tag

In the apparel industry, hang tags are not only carriers of product information but also an important representation of brand identity. While traditional industrial barcode printers can meet basic printing needs, they have significant shortcomings in terms of professionalism, safety, and cost control. In contrast, single tag printers, with their unique technical advantages, have become a suitable tool for apparel brands to enhance quality and efficiency. Here are the key reasons for their advantages:

1. Die-cut hang tag design: preventing sharp corners from damaging clothing

Traditional industrial barcode printers can only print roll-fed hang tags, which require an automatic cutter to trim the edges. This process often results in sharp, jagged, or rough edges that may scratch delicate fabrics such as silk or lace, causing pilling or even damage, ultimately affecting product appearance and customer experience.

Single tag printers support die-cut hang tags, producing pre-cut tags with smooth edges, eliminating the risk of fabric damage. Additionally, die-cut hang tags have neater edges and are less likely to curl when hung, improving the aesthetic presentation of displayed products.

Roll-fed hang tags(left) and die-cut single hang tags(right)

2. Ribbon-saving technology: reducing long-term operating costs

Traditional printers operate with continuous ribbon movement, even when printing blank areas, leading to unnecessary ribbon waste. Single tag printers incorporate ribbon-saving technology, utilizing smart sensors and a liftable thermal print head to control ribbon usage on demand. The ribbon moves only when printing data, reducing idle ribbon consumption and increasing utilization efficiency by over 30%.

Moreover, the thermal transfer technology of single tag printers supports cost-effective wax-based and resin-based ribbons, further lowering material costs. For instance, a mid-sized clothing factory saw its monthly ribbon expenses drop from 5,000 CNY to 1,500 CNY after adopting single tag printing, saving over 40,000CNY annually.

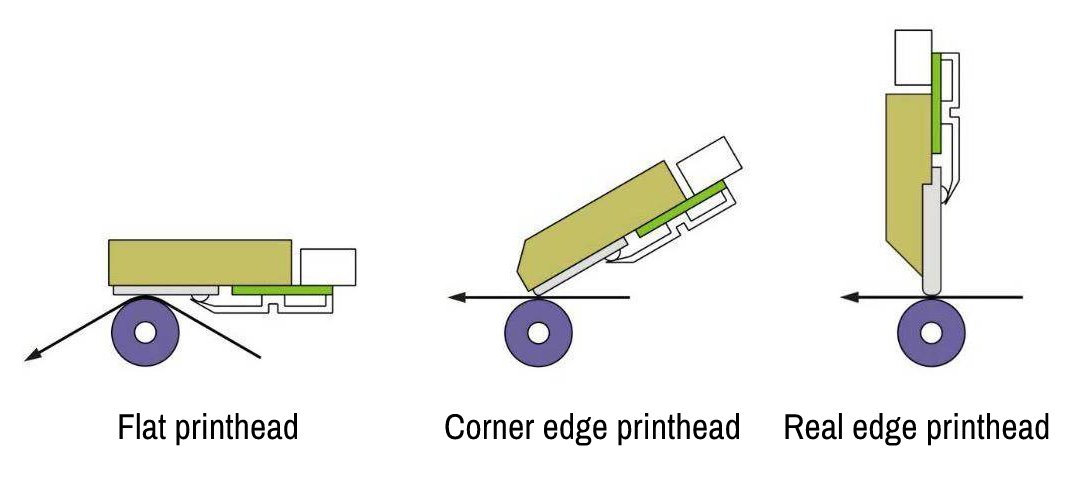

3. Print head design: ensuring flat, non-warped hang tags

Flat thermal print heads in traditional printers often cause hang tags to warp or deform when exposed to heat, affecting their hanging appearance. Single tag printers use edge-mounted or angled print heads that optimize pressure distribution and heating methods to prevent uneven heat application. This ensures a flat final product with a dimensional accuracy of less than 0.1mm, making it suitable for materials such as coated paper and PVC.

This design also extends the lifespan of print heads. Traditional barcode print heads are prone to damage due to repeated impact with paper, whereas single tag printers feature intelligent pressure adjustment to minimize physical wear, extending print head lifespan by 2 to 8 times.

4. Additional advantages: enhancing brand image and production efficiency

- High-precision printing: Most single tag printers support resolutions of 300 dpi or higher, ensuring clear printing of fine text, barcodes, brand logos, and intricate designs, which enhances consumer trust.

- Material compatibility: These printers support a wide range of materials, including 200-500g thick paper, self-adhesive labels, and PVC, catering to the needs of high-end custom apparel brands.

- Automated production: Integration with ERP systems allows automatic generation and batch printing of hang tag information, reducing human error by 90% and improving production efficiency by 60%.

- Environmental sustainability: Compared to roll-fed tags, single tag printing minimizes material waste, supports eco-friendly ribbons and biodegradable paper, aligning with green production trends.

Case Studies and Industry Trends

A fashion brand that adopted single tag printers reduced its per-tag production cost from 0.2CNY to 0.1CNY. Additionally, the improved tag quality enabled the brand to raise its product prices by 15%. Looking ahead, as IoT technology continues to evolve, single tag printers will integrate advanced features such as remote monitoring and double-sided printing, driving the apparel industry toward smarter and more personalized solutions.

Single clothing hang tag printers

Conclusion

By incorporating die-cut safety design, ribbon-saving technology, and optimized print head mechanisms, single tag printers address the pain points of traditional printers while providing comprehensive solutions for brand enhancement and cost control. For apparel businesses that prioritize quality and efficiency, they have become an essential tool for boosting market competitiveness.